Metal swing plate gear for HP Laserjets

This article discusses the swing plate assembly found in the HP Laserjet 4200, 4250, 4300, 4350, and 4345MFP printers. The swing plate assembly drives the pressure roller gear in the fuser. It is well known that the swing plate assembly in these printers fails prematurely. To solve this problem PrinterTechs has developed and manufactured a metal gear and bearing assembly which we will simply call the "metal gear". This gear has been heavily tested to over a million pages worth of use, and thousands of metal gears are currently out in the field.

This is a rough sketch showing how the gears are oriented in the printer. It is worth noting we put a sealed bearing in the center of the brass gear to smoothen out the rotation, reduce wobble and friction. In HP's gear, the plastic bore wears down causing the gear to wobble slightly on its axel.

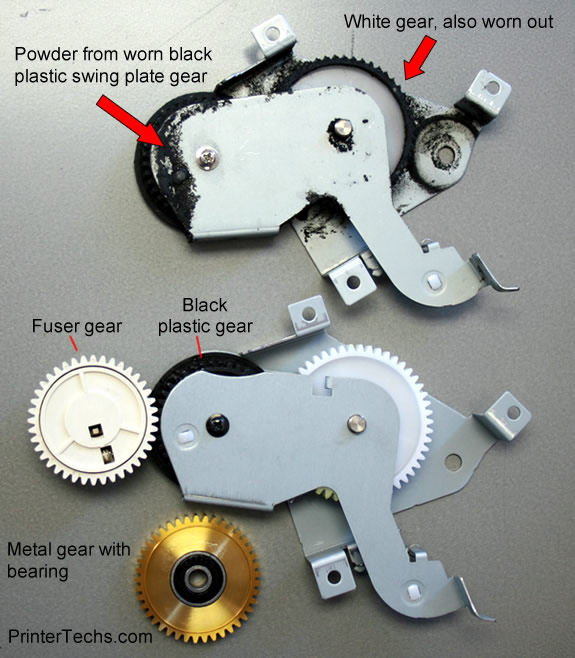

Below are pictures of a worn out swing plate assembly, an new swing plate assembly, and the PrinterTechs metal gear.

There is a lot of abrasive material floating around the swing plate assembly. Not only is there a lot of toner, paper dust, and environmental dust and dirt, but as the black plastic gear starts to wear it sheds a plastic powder that causes abrasion. Often we will see worn gears with black plastic powder sticking between the teeth (see above picture) and black powder piled up underneath the gear. The metal gear eliminates the presence of the black plastic powder and is more resistant to abrasion from the remaining contaminants.

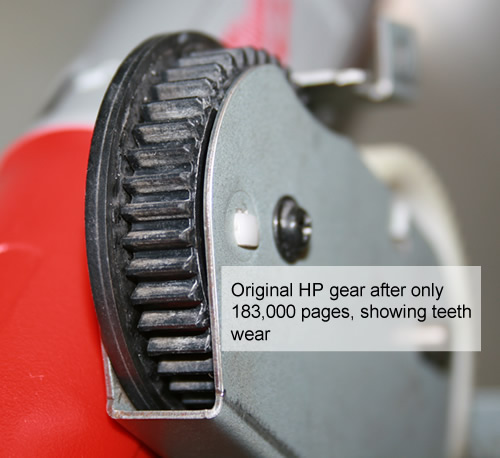

So why is there so much gear wear with the original swing plate gear? Besides the abrasion, the plastic gear doesn't seem durable enough for all of the pressures and movement (wobble) in the fuser. The whole purpose of the swing plate assembly is to drive the fuser. The swing plate gear couples with the gear on the fuser's pressure roller. In a perfect world the fuser would not move and the gears would only rotate around their axis without any other movement. In reality, even though the fuser is locked in place it still has some play. Watch the fuser as the printer starts, you'll see a small movement as the fuser engages. All of this movement, vibration, and abrasion cause the teeth to wear.

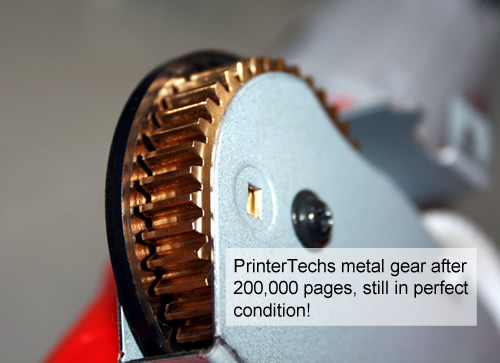

Occasionally we will get asked, won't the metal gear wear out the plastic gears? No. Over time, our metal gear causes LESS wear on the white plastic gear, not more. You have to think about how gears work. Gears aren't like knives which have a very sharp cutting edge. Gear teeth have flat surfaces that move across each other. Here is a good link describing gear wear and failure http://www.mt-online.com/component/content/article/177-january2000/570-failure-analysis-for-gearing.html

Coefficients of friction are important to consider. Gear teeth slide across each other during rotation thus the sliding friction between gear materials is very important. Gear teeth of similar materials result in higher friction (in non-lubricated systems) than dissimilar materials. Here are some examples of sliding friction for different materials. The lower the number, the lower the sliding friction. Lower numbers are better.

• Coefficient of sliding friction for steel on steel is ~0.8

• Coefficient of sliding friction for Nylon-Nylon is ~0.35

• Coefficient of sliding friction for polyethylene on steel is ~0.2

The higher sliding friction of plastic teeth on plastic teeth causes higher wear than metal teeth on plastic teeth.

If you still have doubts about metal and plastic gears working together, consider that HP has used metal gears with plastic gears in several printers where plastic just didn't offer enough wear resistance. For those who have worked on Laserjets 8100 & 8150 the gear that drives the fuser is metal, the Laserjet 4-Plus has a metal gear in the fuser (RS5-0231), and there also was a metal gear in the 5si/8000 fuser (RS5-0751).

And finally we have real world and test results for the metal gear. Our testing utilized a combination of in-printer testing and accelerated wear testing where we hooked up an external motor to the printer's main gear drive and increased the speed to the equivalent of 110 pages per minute. This was a much tougher load on the gear than normal operating conditions. The friction forces were a lot higher in the fuser due to the increased speed and the heating element grease not being heated to the normal ~392 F temperature. We stopped testing after 1,000,000 pages worth of rotations, and the gears still worked flawlessly. Out in the field, we haven't seen or heard of any of the metal gears or the white plastic gears wearing out. Read more here HP LaserJet swing plate assembly upgrade

We occasionally hear objections over price. Many people are cheap to a fault, and fail to consider the monetary value of time. They feel proud of themselves for being able to buy the plastic version of the swing plate assembly for $10-$20, and balk at the price of the metal gear for $65. However, time is money. How long does it take the average tech to replace a swing plate assembly? Over an hour for most techs. And what is the fully loaded labor rate for an onsite technician? How long does it take to drive to the location of the printer? How much productivity is lost due to down-time? Add it all up and tell me how much you lose by having to service the printer again because of a worn plastic swing plate gear.

Keep in mind that many service companies are paid per repair and make a lot of money on service fees. Installing a permanent fix like the metal swing plate gear won't give them the potential for future service calls to replace the swing plate again. However from the end users perspective this gear saves them money by preventing future service calls. Think about it, the $30-$50 premium for the metal gear is a lot cheaper than another service call, which in most US markets would be AT LEAST $150-$200. And for service companies utilizing the managed print services model (MPS), the metal gear might be a wise investment if they have high volume HP 4200, 4250, 4300 or 4350 printers under contract.

By Jeff Niemeyer, Printechs

To purchase the metal swing plate gear click here, buy the metal swing plate gear