PrinterTechs refurbished printers

"I found a refurbished printer at a cheaper price, why should I buy yours?"

"I found a refurbished printer at a cheaper price, why should I buy yours?"

There is no industry standard for printer refurbishing. To some companies refurbished means “it works”, to others it means blowing the dust off and replacing a few rollers, but not to us. We take great pride and care in our refurbished printers. When a technician spends more time thoroughly rebuilding a printer, replaces more parts, and uses a higher grade of parts, it is simply going to cost more for that printer. But the end result is a printer that won't give you that nagging feeling that you just bought a lemon.

PrinterTechs printer innovations and upgrades

Because we repair and rebuild printers all day we see what parts fail -- and this has led us to several innovations and upgrades that you won't find anywhere else.

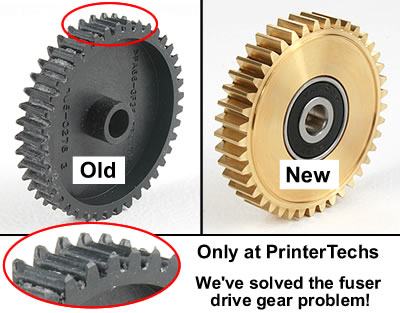

One of our most recent upgrades is the metal swing plate gear in the LaserJet series 4200, 4250, 4300, and 4350. The swing plate assembly has been a major problem with these printers. The original gear is the black plastic gear pictured to the left. We've seen this gear wear out in as little as 110,000 pages. That's about half a maintenance cycle.

Why hasn't anyone else come up with this solution? Creating prototypes, setting up special test equipment, and testing is time consuming and expensive. Other companies keep replacing the plastic gear with another plastic gear. It's cheaper, but not if you value your time. Use a quality gear and you won't need to replace it again. We've done the research, you get the benefit: a custom- manufactured solid brass replacement gear with a high speed bearing. This solves the gear problem once and for all. You won't find this anywhere else!

Why hasn't anyone else come up with this solution? Creating prototypes, setting up special test equipment, and testing is time consuming and expensive. Other companies keep replacing the plastic gear with another plastic gear. It's cheaper, but not if you value your time. Use a quality gear and you won't need to replace it again. We've done the research, you get the benefit: a custom- manufactured solid brass replacement gear with a high speed bearing. This solves the gear problem once and for all. You won't find this anywhere else!

Read more about the swing plate problem and solution.

Another wildly popular PrinterTechs innovation is in the LaserJet 4200 series fusing assembly. The LaserJet 4200 series was designed by HP with a plastic fixing film (sleeve). This sleeve is notorious for shredding and tearing as shown to the left. We have successfully integrated metal sleeve technology into the 4200 series printers (as well as the 4250, 4300, and 4350 series printers). The metal sleeve is highly tear resistant and a much more robust than the plastic sleeve.

Another wildly popular PrinterTechs innovation is in the LaserJet 4200 series fusing assembly. The LaserJet 4200 series was designed by HP with a plastic fixing film (sleeve). This sleeve is notorious for shredding and tearing as shown to the left. We have successfully integrated metal sleeve technology into the 4200 series printers (as well as the 4250, 4300, and 4350 series printers). The metal sleeve is highly tear resistant and a much more robust than the plastic sleeve.

Read more about the metal fixing film in our LaserJet 4200 maintenance kits.

Upgraded bushings LaserJet 2400, 2420, 2430, P3005, 1320, P2015, 1200, 1300.

Sometimes it's the little things that make the difference. The original OEM fuser bushings in the above mentioned printers are terrible. We've seen them wear out in as little as 50,000 pages. The pressure roller shaft pictured to the left rotates directly on the bushing. As the bushing wears down a gap forms causing the pressure roller gear to slip and grind in the printer - all because of some cheap bushings. We use an upgraded aftermarket bushing that outperforms the OEM.

Sometimes it's the little things that make the difference. The original OEM fuser bushings in the above mentioned printers are terrible. We've seen them wear out in as little as 50,000 pages. The pressure roller shaft pictured to the left rotates directly on the bushing. As the bushing wears down a gap forms causing the pressure roller gear to slip and grind in the printer - all because of some cheap bushings. We use an upgraded aftermarket bushing that outperforms the OEM.

If you have any questions about what printer would best fit your needs give us a call or email. The LaserJets mentioned above (1200, 1300, 1320, P2015, P3005, 2400, 2420, 2430) are considered personal printers. They aren't designed for heavy business use like the 4000 series and higher workgroup printers. We'd be happy to advise you on the best printer for your needs.

Quality Tested Parts

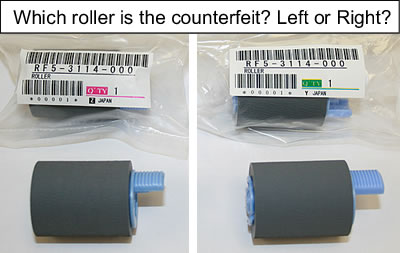

In pursuit of the highest quality parts for our printers we do a lot of testing. Most companies do little if any testing and simply use the cheapest parts they can find. But cheap price usually means cheap quality, which leads to feed problems, paper jams, and premature failure. To illustrate how important it is to test parts quality, look at the rollers to the left.

In the picture above, one set of rollers is a fake. They look just like real genuine HP parts but in reality they are counterfeit. They failed to pickup paper 50% of the time we tested them.

So which one is the fake?

Click here for the answer.

Hidden Fixes

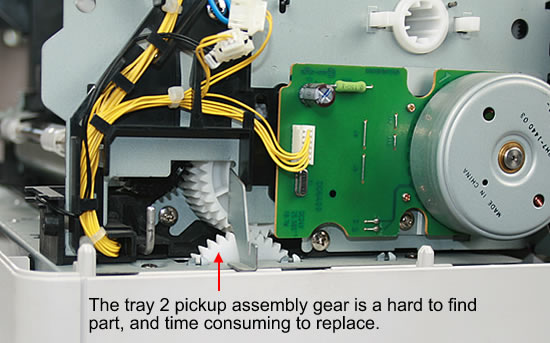

The picture above shows the tray 2 pickup assembly gear found in the Laserjets 4000, 4050, and 4100 series printers. We are probably the only company that bothers to replace this gear when it wears out. The gear is hard to procure and and time consuming to replace.

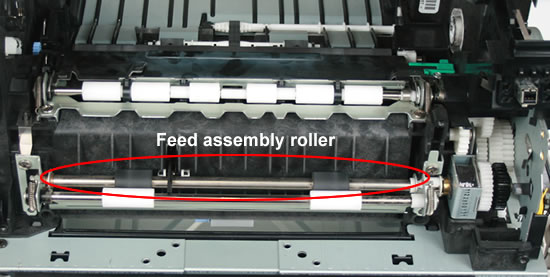

Below is another hard access roller found in the LJ 4000, 4050, 4100, 4200, 4250, 4300, 4350. This is an OEM part that we have custom machined to be universally compatible on all of the 4xx0 printers. This is another assembly that many companies ignore since it is hard to procure and requires the removal of the manual feed tray pickup assembly to access.

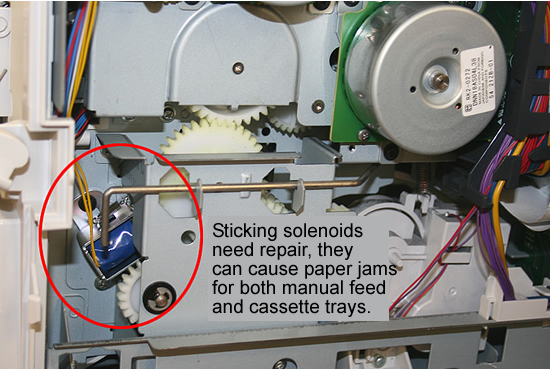

We inspect the pickup assembly solenoids on our printers, and repair them. Many companies don't inspect the solenoids, because it requires them to disassemble the printer. Solenoids have a sound-dampening pad which can decay over time, and the remaining substance can stick and cause intermittent paper jams from either the cassette tray or the bypass tray.

For those in need of 11x17 printing we often recommend the Laserjet 5000 and 5100 series printers. Below is a main gear assembly with a new fuser drive gear and swing arm gear. This is another part that many companies ignore.

The rebuild process

The printer rebuilding process is quite extensive and each model has its own unique requirements. A general outline would include disassembly and cleaning, rebuilding paper path and mechanical assemblies, touching up electronics, final testing and QC, and packaging.

Disassembly and cleaning – exterior plastic panels and paper trays are removed and washed, mechanical assemblies are removed and prepped for rebuilding, and the printer interior is cleaned.

|

|

Mechanical and paper path assemblies – this is the bulk of the rebuild process. These assemblies include pickup assemblies, feed assemblies, registration assemblies, fusing assemblies, delivery assemblies, and gear assemblies. Each model has its own unique rebuild requirements and idiosyncrasies which emphasizes the importance of having experienced techs. On large printers like the 8100 and 8150's it can take the better part of a day to rebuild and install all of the assemblies.

|

|

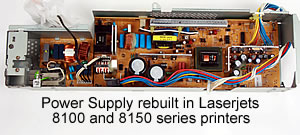

Electronics – electronics in laser printers are generally very reliable-- however, laser scanner lenses and mirrors must be cleaned, power supplies in LJ 8100/8150 must be rebuilt, and some models need firmware upgrades.

|

|

After the printer is reassembled it goes through final testing and quality control.

Custom foam-in-place packaging is used to ensure safe transit of the printer.